News

Over 200 Attend Road2Composites at Michigan State University

Industry Elite Attend Two-Day Workshop presented by Composites One and IACMI-The Composites Institute

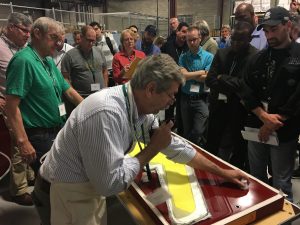

Over 200 students, academics, technicians and business owners now have a better understanding of the latest developments in composites, advanced materials and processes, thanks to attending Road2Composites, a two-day workshop presented by Composites One in partnership with the Institute for Advanced Composites Manufacturing Innovation (IACMI), one of eight organizations comprising the National Network of Manufacturing Innovation. The workshop was held at Michigan State University in East Lansing, Michigan, and was also supported by Magnum Venus Products (MVP).

“Composite materials have a unique place in the evolution of the transportation industry to meet CAFÉ standards that require light weighting to meet fuel efficiency standards. When we developed this workshop it was our goal to help prepare the next generation of composites professionals in the automotive and transportation space, as well as ensuring that our industry’s existing workforce is up to speed on the latest technologies,” said Composites One Vice President of Advanced Composites Dwight Baker. “Judging by the comments that we heard from attendees, we’re on our way to achieving that goal.”

At the workshop, IACMI CEO, Bryan Dods, spoke about the State of Michigan’s leadership on automotive technology and its commitment to partnership in workforce development, stating, “Michigan has rightfully earned its reputation as an automotive manufacturing leader and technology innovator. Training events for the over 70 companies represented at the workshop would not be possible without the support through the Michigan Economic Development Corporation (MEDC).”

Held May 16-17 at the Composite Vehicle Research Center in Lansing, Michigan, the Road2Composites workshop focused on scale-up, light weighting and high volume composites products and processes. During this two-day workshop, attendees attended programs focusing on fuel efficiency, design freedom, and manufacturing efficiency and how they have been driving transportation and automotive materials and process development toward composites for years. This workshop was dedicated to demonstrating composites for both transportation (lower volume) and automotive (higher volume). Whether attendees were responsible for the manufacturing of buses or pickup trucks, SUVs or Humvees, racecars or sedans, there was something for all present.

Representatives from over 70 companies, including GM, Toyota, and Tesla, and over 200 industry experts attended the two-day Road2Composites workshop. The event was made possible through the support of Composites One, IACMI-The Composites Institute, Michigan State University and the Michigan Economic Development Corporation.

“The Road2Composites workshop would not be possible without the expertise and support of our supplier partners,” said Baker. They include 3A Composites, Acra Lock, Arkema, ChemTrend, Chomarat, Gurit, Huntsman, Lantor, MVP, Owens Corning, Polynt, Polystrand, Proset, Scott Bader, Sika Axson, and SWORL.

Following this event will be one more Composites One – IACMI workshop presented this year at Purdue University in Indianapolis (check compositesone.com for dates and registration details), November 7-8.

Workshops are developed to expose participants to a variety of processes, systems, modeling software, equipment and materials including closed molding, out-of-autoclave production, additive manufacturing (3D printing), prototyping, and advanced materials with high strength to weight ratios selecting. Sessions are led by experienced process experts from Composites One and the Closed Mold Alliance, a resource dedicated to helping manufacturers make a successful conversion to closed mold and other advanced processes, and IACMI. Along with Composites One, the Closed Mold Alliance founding members include Magnum Venus Products and RTM North Ltd.