News

Peel Ply from Aerovac Helps with Surface Preparation

Aerovac offers the process materials that composites manufacturers need to ensure easy application, curing, and removal of composites from the surface mold. Peel ply is a process material that is integral to achieving an effective, uniform surface preparation as part of a prepreg processing/vacuum bagging process.

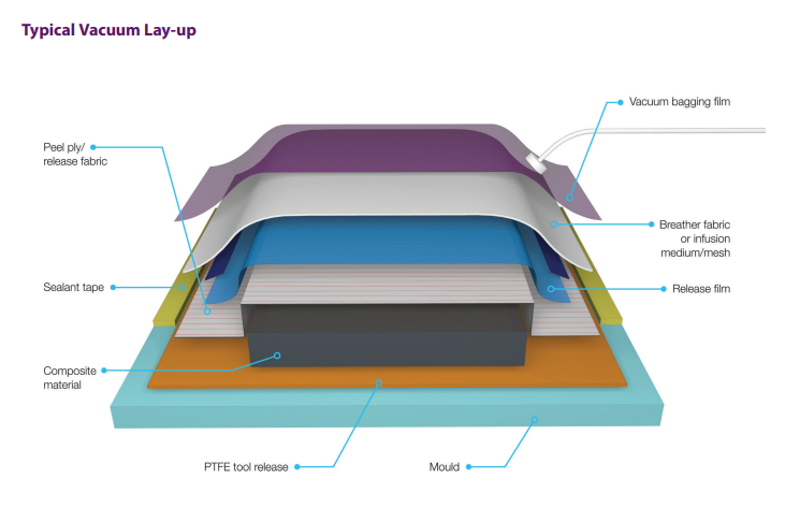

In a vacuum application process, peel ply fabric, or release fabric, is layered between the composite materials and the release film to ensure a solid bond and release. Peel ply is available in standard formats, slit widths, and cut-to-shape formats to meet the application process requirements.

Peel ply layers on surface quality and bond performance in the vacuum process

Several layers of process consumables are needed in the vacuum process to apply over the mold, tool release, and composite materials. These process materials include the peel ply, release film, breather fabric or infusion mesh, sealant tape, and vacuum bagging film. Vacuum pressure is applied for part consolidation, followed by heat and/or pressure as required for the curing process.

According to Composites World, “How a peel ply releases from the composite substrate to be bonded controls the surface quality and thus bond performance.” To that end, some peel plies have adhesive backing for easier application and removal of consumables during the manufacturing process.

Peel ply is available in multiple materials and formats from light to heavyweight nylon and polyester woven fabrics. According to a study in Composites World, “the best peel ply in testing results is fine-weave, polyester fabric pre-impregnated with resin.”

Peel plies also come in wet and dry forms. Wet peel ply is a pre-impregnated polyester peel ply product that requires no sanding, solvent wiping, or any further steps, to expedite the processing steps needed to achieve a consistent surface for composites manufacturing. It can provide a more durable bond than dry peel ply fabrics.

Aerovac peel ply products are available in multiple materials and formats to offer flexibility in options and to match application requirements. Light to heavyweight woven fabrics are available in both nylon and polyester, and some are also available with adhesive backing to simplify the consumable application process. Peel ply is available in standard formats, slit widths, and cut-to-shape formats.

With high-quality peel ply and other vacuum bagging and process materials from Aerovac, plus the unparalleled support of technical experts from Composites One, manufacturers have the resources they need to meet processing and application requirements.

Learn more about peel ply products and support from Composites One and Aerovac.