News

Process Materials Kitting Services from Aerovac are Packaged with Technical Support

The benefits of custom process material kitting solutions are undeniable. Saving time and money and reducing waste and human error in composites manufacturing just scratch the surface. Optimized processes, increased productivity, manufacturing efficiencies, and improved quality can all be achieved by using Aerovac’s kitting services.

Aerovac is a leader in the composite industry, providing high-quality vacuum bagging and process materials used in prepreg processing, vacuum infusion, glass lamination, and other industrial applications. Especially for manufacturers with complex parts or specific manufacturing requirements, Aerovac offers kitted process materials as a risk-reduction solution to meet the challenges of complex, expensive part processing. With customized solutions to meet these challenges, Aerovac is the global industry leader for kitted process materials.

The dedicated customer support team at Aerovac guides manufacturers in selecting the proper kitting solutions to maximize savings in time, cost, and manual operator resources, offering complete technical support through the manufacturing process. With deep knowledge of composites materials and manufacturing processes and techniques, Aerovac helps customers select, implement, and optimize customized kits in unique manufacturing operations.

Aerovac process material kits are tailored to the composites manufacturing environment and application

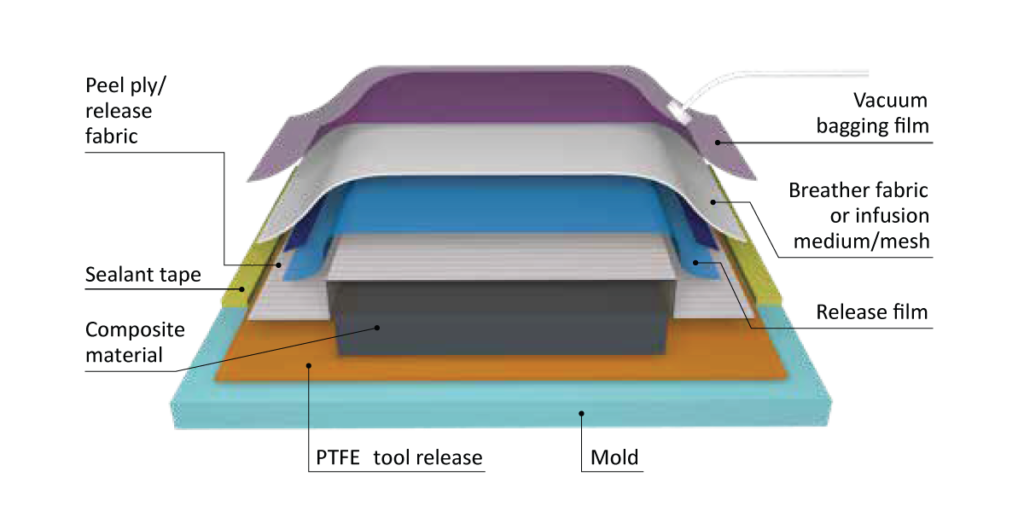

Aerovac’s kitting service includes pre-cut consumables for simple, predetermined shapes and dimensions, to the assembly of complex, multi-layer integrated vacuum bag assemblies – enabling customers to stay focused on their manufacturing operations. During customer engagement, the technical experts at Aerovac identify requirements, configure solutions, assist with manufacturing the first sample, and support sustained production of the efficient new process using custom kits.

Aerovac’s highly skilled engineers design complex, tailored kits, and bag assemblies to simplify the manufacturing process for composite structures, regardless of the required size and quantity. The design and prototyping process ranges from defining individual layer profiles to designing customized packaging for safe delivery of a complex bagging assembly, direct to the manufacturing line, as necessary.

At Aerovac and Composites One are Technical Support Team is available to customers at the local and regional level, for questions or on-site support as needed, so manufacturers can begin to identify efficiencies for composites manufacturing processes. Our Team can assess current operations and identify opportunities for custom kits to improve production to meet demand on time and on budget.

The boundless benefits of kitting

Digging deeper into the efficiencies of kitting, benefits include the opportunity to reduce manufacturing time by more than 50% and reduce materials waste by an average of 40%. Other measurable improvements include:

- Creating process repeatability with quality and consistency

- Increasing productivity

- Improving health and safety for employees through reduced handling

- Improving mold usage through reduced cycle times

- Reducing part-to-part variation and improving bag consistency

- Standardized working practices

- Reducing operator dependency

- Simplifying vacuum bagging process

Our industry-leading technical support educates manufacturers on product usage, specification requirements, and process technologies like vacuum infusion and advanced prepreg processing. The Aerovac and Composites One Technical Support Team is ready to assist customers on proper techniques and best practices through both on-site and digital channels that include workshops and webinars.

Learn more about kitting solutions from Aerovac, the global leader for process material kitting.