Open Molding

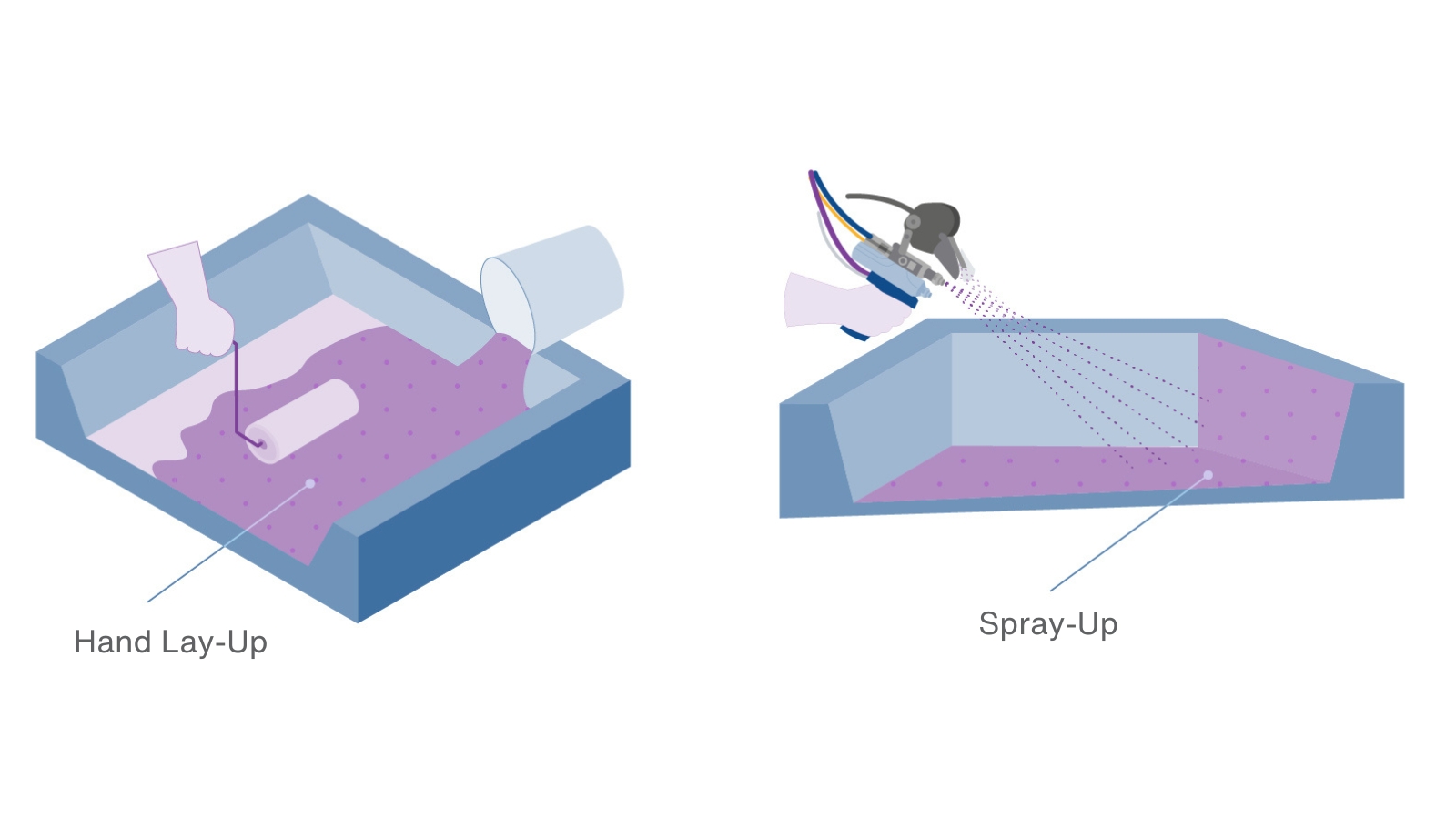

Process Overview: Hand Lay-Up & Spray-Up

Hand lay-up and spray-up are commonly used, cost efficient open mold processes in which resin and reinforcements are either laid by hand, or sprayed onto a mold to achieve the desired physical characteristics of the part.

After mold release is applied to the mold surface, gelcoat is sprayed or brushed onto the mold and allowed to cure. Gelcoat is used in many applications, but not all. With the hand lay-up process, fiberglass reinforcement materials are manually placed into the mold, ensuring proper coverage and alignment for optimal structural integrity of the final part. Laminating resin is then applied onto the fiberglass reinforcements by pouring, brushing, or spraying. With the spray‐up method, multi‐end glass roving and catalyzed resin are applied via a chopper gun, which deposits the resin‐saturated “chop” on to the mold. In both applications, tools such as rollers or squeegees are used to remove any entrapped air in the laminate, create uniform thickness, and ensure thorough wetting of the reinforcements. For added strength and stiffness, low‐density core materials, such as end‐grain balsa or foam, may be incorporated. The part is allowed to fully cure before demolding.

Example Hand Lay-Up & Spray-Up Applications

Boats

Storage tanks

Bathtubs and showers

Machinery and tools

Surfboards, bicycles, and sports gear

Automotive panels and structural components

Technical and HSE Support for Hand Lay-Up & Spray-Up

Composites One offers personalized technical support for customers manufacturing with the process of hand lay-up and spray-up, as well as the most up-to-date information on regulatory and compliance requirements.