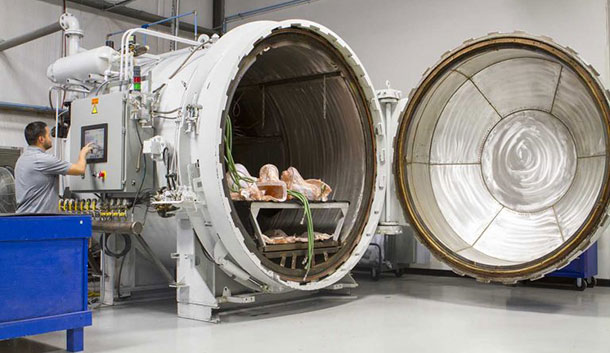

Autoclave

In the production of composite aerospace and aircraft components, autoclave curing has traditionally been used to achieve the desired fiber content (resin-to-fiber ratio) and the absence of resin voids to produce light weight and strong components. Autoclave curing achieves this by placing the part under vacuum in an autoclave and then pressurizing the autoclave during the heated cure cycle. The high pressure on the part (within the pressurized autoclave) helps to minimize resin voids and to achieve the desired resin/fiber ratio.