Vacuum Infusion Process

Process Overview: Vacuum Infusion & Vacuum Bagging

Vacuum infusion using vacuum bagging and process materials are advanced closed mold composites manufacturing processes that create strong, lightweight parts by minimizing air entrapment and optimizing the fiber-to-resin ratio.

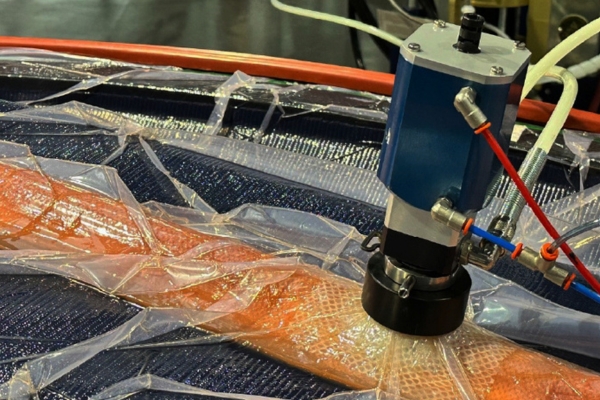

The vacuum infusion process starts with placing dry fiber reinforcement materials, such as fiberglass or carbon fiber, into a mold to maximize structural properties. Core materials can also be incorporated to improve part stiffness and physicals. Perforated release film and breather cloth are placed over the laminate followed by the vacuum bag which is made of thermoplastic film. The bag is sealed over the entire assembly and a vacuum is applied. Catalyzed resin is introduced into the mold through resin injection ports fully wetting out the laminate as air is eliminated via the vacuum. The part is allowed to cure with or without the addition of heat, the bagging materials are removed, and the part is demolded.

Example Vacuum Infusion & Vacuum Bagging Applications

Marine hulls and decks

Aerospace parts such as interior cabin components

Wind turbine blades

Specialty automotive body panels, spoilers, and structural components

Architectural panels and facades

Industrial and construction components

Sporting goods

Technical and HSE Support for Vacuum Infusion & Vacuum Bagging

Composites One offers personalized technical support for customers manufacturing with the process of vacuum infusion and vacuum bagging, as well as the most up-to-date information on regulatory and compliance requirements.