News

Breather Fabrics from Aerovac

Aerovac is a featured supplier of Composites One that develops, manufactures, and supplies innovative process materials to the composites industry. Its vacuum bagging and consumables, infusion materials, and reusable vacuum systems are used by composites manufacturers in prepreg processing, resin infusion, hand layup, filament winding, compression molding of thermoplastic composites, and glass lamination.

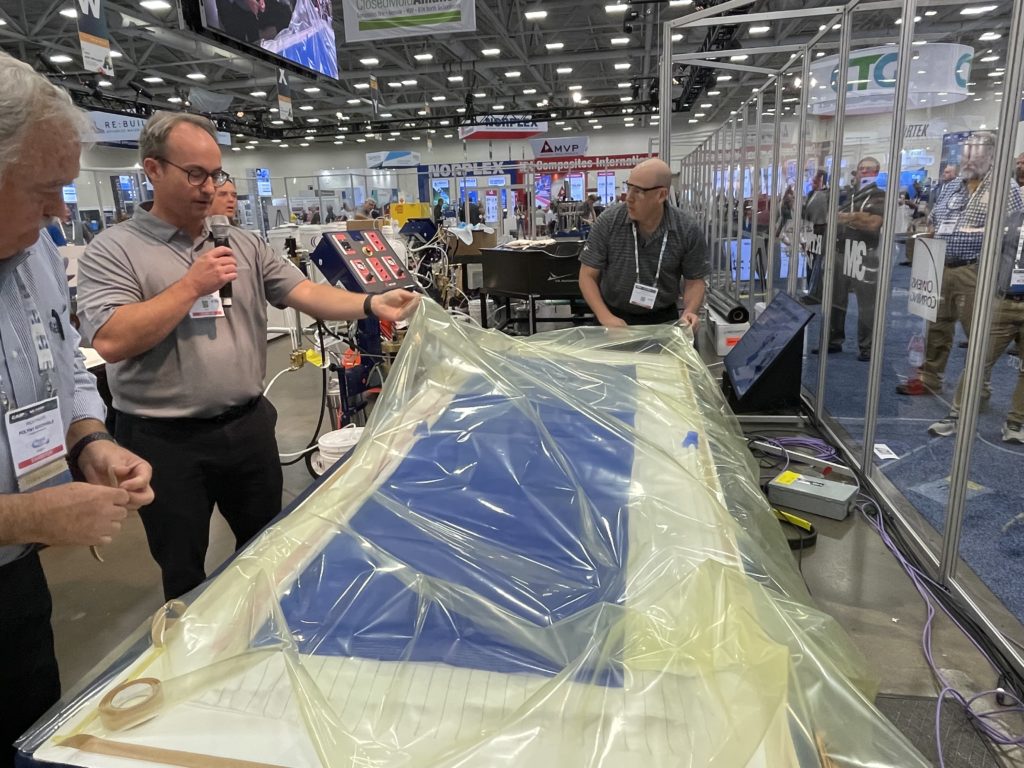

Aerovac vacuum bagging and process materials are critical to performing successful vacuum bagging processes. This includes breather fabric, a 100% non-woven polyester or nylon fabric that is designed to allow airflow throughout the vacuum bagging process as well as bleed out an excess resin in a composite part. Breather fabrics allow significant conformity around a composite part while under vacuum pressure.

Breather assemblies like breather fabric is used during vacuum curing. Along with the vacuum bag, it is placed over the layup and attached to the tool, then a vacuum is pulled prior to initiation of cure. As described in Composites World, this vacuum bagging process further consolidates the plies of material and significantly reduces voids due to the off-gassing that occurs as the matrix progresses through its chemical curing stages.

Breather fabrics are available for unique manufacturing requirements

Breather fabrics are available in standard roll formats, slit widths, cut shapes, 3D stitched formats, and in a variety of weights. They can be tailored specifically to meet customers’ manufacturing and applications requirements. Polyester, nylon, and E-glass breather products for both surface and edge breathing are available, with breather areal weights from 85 gsm to greater than 650 gsm.

For breather fabrics and its other process materials, Aerovac offers custom kitting solutions that reduce labor, minimize waste and improve quality on the production floor. By using custom process material kits that are pre-cut and tailored to the manufacturing specifications, manufacturers can cut material waste by an average of 40%, lower costs, increase operator productivity and reduce margin for error.

Learn more about the importance of breather fabrics in the vacuum bagging process.