News

How to Perform a Resin Infusion Drop Test

In vacuum infusion composites manufacturing, the resin infusion process uses a vacuum to draw resin into the laminate within an open mold. This process involves several vacuum sealing components. The vacuum bag, sealant tape, and the tool must be vacuum-tight. Before you begin the actual infusion, one of the most important aspects of the resin infusion process is to perform a vacuum pump off-timed drop test to ensure optimal vacuum integrity on the tool.

How to perform a drop test

Once you have completed vacuum bagging the part, check to make sure it is vacuum-tight by using a digital gauge to pinch off a line that goes back to the pump. The absolute atmospheric pressure will vary from day to day and location, and results may also vary depending upon the type of part and industry application, yet an acceptable drop test result is < 1 inch Hg in five minutes. Anything beyond a five-minute result will likely pull air into the system during resin infusion.

If you detect a leak, check the sealant tape by pushing the tape into the tool flange and squeezing the bag pleats. A significant leak will inhibit the flow of the resin and the extraction of the air under the bag.

Case study – 5-minute vacuum drop test

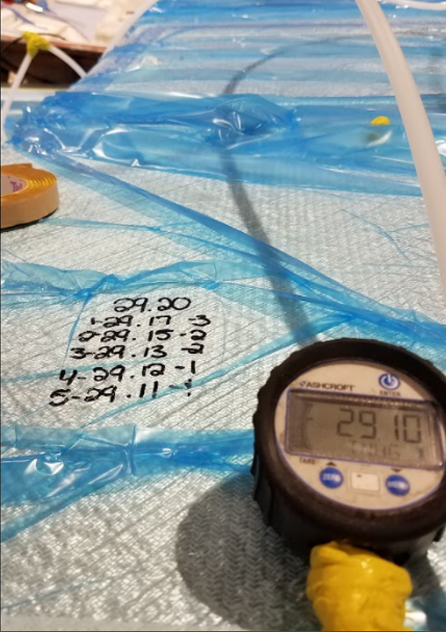

The starting vacuum level was 29.20 inches Hg. The part was then isolated from the vacuum pump. The markings on the vacuum bag show the vacuum level at each minute during the test.

- 29.17

- 29.15

- 29.13

- 29.12

- 29.11

The overall drop in five minutes with the vacuum pump off was 0.09 inches Hg, which is much lower than the one-inch Hg acceptable drop. The part passes the drop test. If the drop was more than one inch Hg in five minutes, the operators would need to check the part for leaks.