News

Infusing Efficiency into Aerospace Production

Autoclave prepreg has long been the de facto process for most large and mid-sized aerostructures. Today, advancements in resin infusion processes are helping to produce composite-based structural aircraft components completely out of the autoclave and at up to one-tenth of the cost—and all the performance.

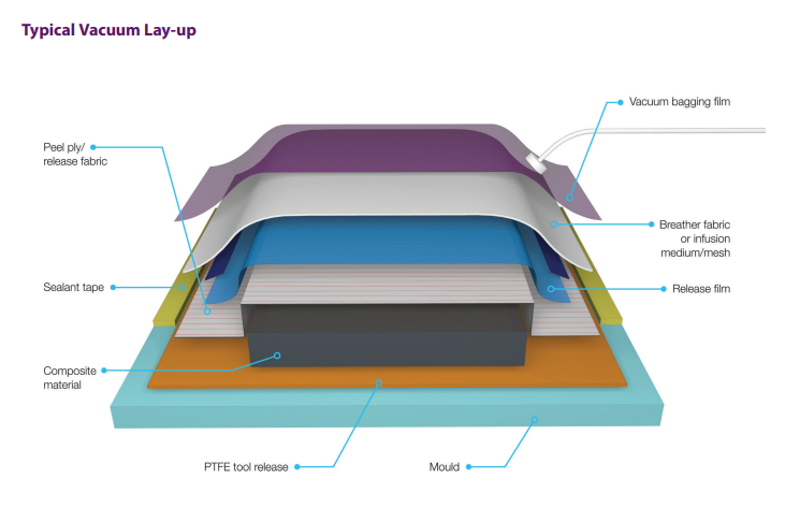

Aircraft manufacturers have sought methods to expedite composites component production through processes that are not limited by an autoclave. Success has come in the form of composite wings being produced using the completely out of autoclave process of vacuum infusion. The vacuum infusion process molds resins and fibers with extreme consistency and precision through the power of vacuum suction.

The aerospace industry is after lighter-weight parts with a higher load-carrying capability. As vacuum infusion saturates resin into the fibers through the vacuum process, it allows for ideal part-to-part variability of fiber content thickness for exceptional fiber-to-resin ratio and optimal performance.

Aerospace and composites go hand in hand

The aerospace market has been a great contributor to the utilization of advanced composites materials and processes. Flying successfully today are vacuum infused critical primary wing structures that include the wing strings, wing spars, and wind box—without the use of an autoclave. Also flying today is the Boeing 787 aircraft, which has over 50 perfect carbon structures.

With smaller, newer model aircrafts expected to meet production demands of 100 units per month, manufacturers continue to explore infusion processes and materials that can deliver lower material expenses with less resin waste and environmental exposure, plus shorter cycle times through saving production steps from traditional assembly and mechanical fastening processes.

As technologies advance, so does aircraft performance

Drastic improvements in resin technology have solved early-on processing challenges that limited the viability and traction of resin infusion in the aerospace industry, including inadequate durability and damage tolerance with original RTM resin systems. With today’s resin infusion processes, manufacturers are no longer constrained by prepreg materials and can achieve more efficient structural performance per weight. They are also realizing cost benefits in both the recurring and non-recurring costs of resin infusion processes vs. prepreg autoclave.

Composites One has an extensive advanced composites product line available to aerospace manufacturers, including many specified products, plus unparalleled technical assistance to educate customers on effective process implementation. Each of our technical support managers brings over two decades of experience with infusion technology across multiple market segments including aerospace.