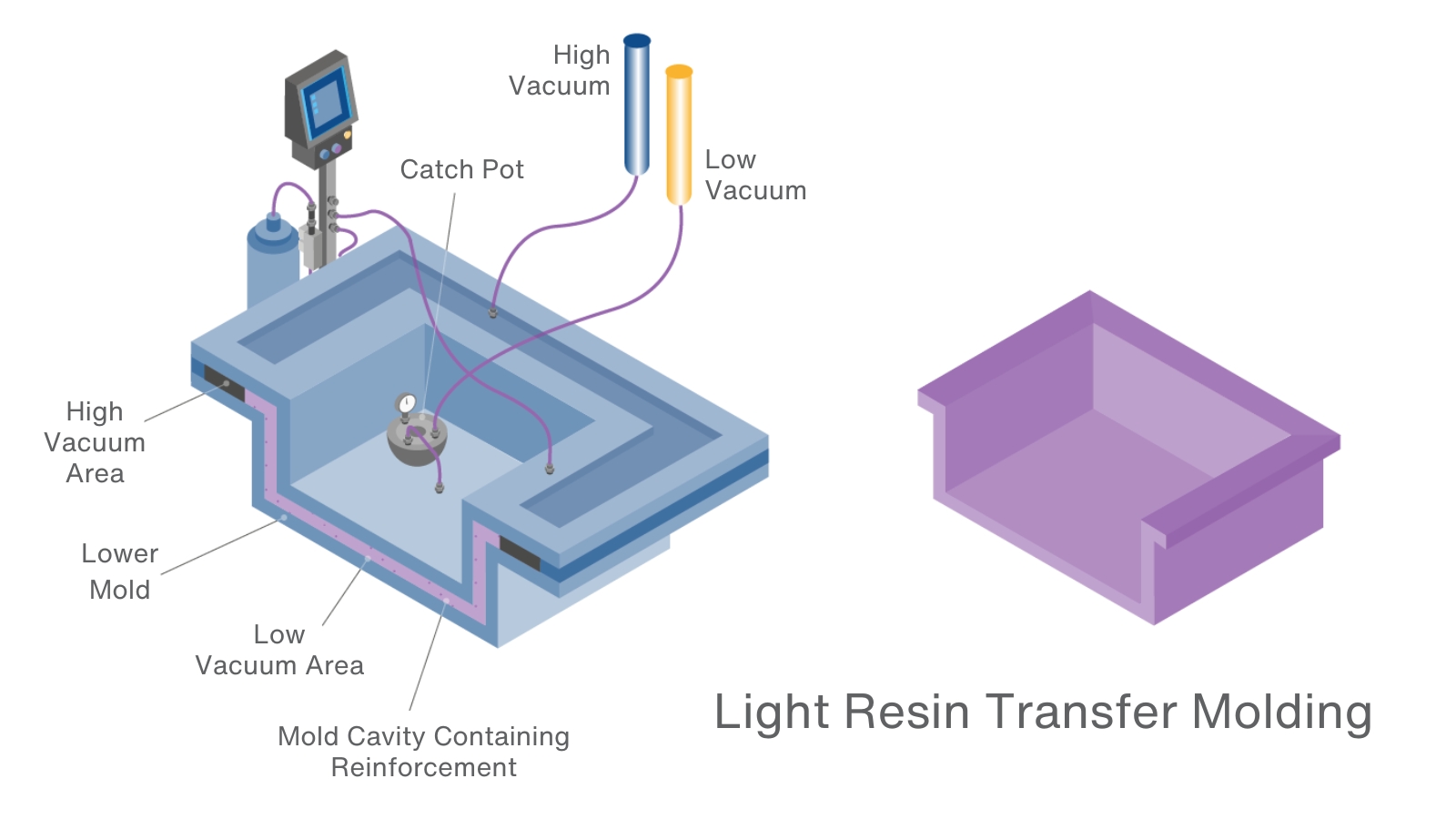

Light Resin Transfer Molding

Process Overview: Light Resin Transfer Molding

Light RTM is the closed mold process of infusing dry fiber reinforcements with resin in a dual‐sided mold cavity under vacuum to produce a variety of composite parts with a high‐quality finish on both sides.

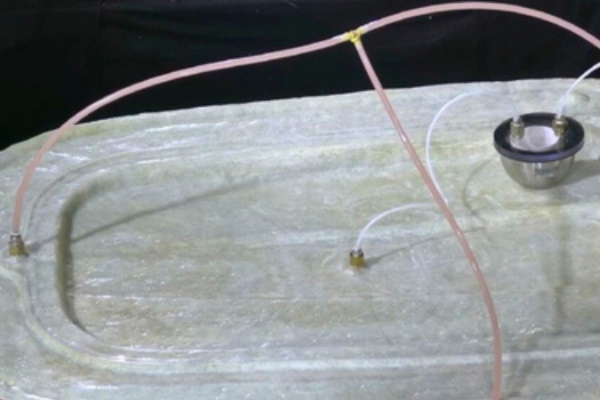

The process of LRTM uses a rigid base or A-side mold and a semi-rigid B-side mold that incorporates seals along the peripheral flange to facilitate vacuum pressure and resin infusion. Reinforcement materials such as knits, mats or infusion products are layered into the mold. Core materials such as foam or balsa may also be added to increase part stiffness. Once all materials are placed, the two matching A and B-side molds are closed and clamped, and a vacuum is applied. When vacuum pressure is achieved, catalyzed resin is injected into the mold via an injection port. Vacuum pressure is maintained until the cavity is filled and cured with subsequent vacuum release and demolding of the part.

Example Light RTM Applications

Automotive body panels, bumpers, dashboards, and interior parts

Boat hulls and decks

Sports equipment such as helmets, kayaks, and bicycle frames

Industrial equipment such as covers, guards, and machine casings

Wind turbine nacelles and smaller turbine blades

Enclosures for diagnostic devices and imaging equipment

Technical and HSE Support for Light Resin Transfer Molding

Composites One offers personalized technical support for customers manufacturing with the process of light resin transfer molding, as well as the most up-to-date information on regulatory and compliance requirements.