Reusable Bag Molding

Process Overview: Reusable Bag Molding

Reusable bag molding is a cost-effective closed mold process of infusing dry fiber reinforcements with resin under vacuum using a reusable vacuum bag over an A-side mold instead of a disposable vacuum bag or rigid B-side mold.

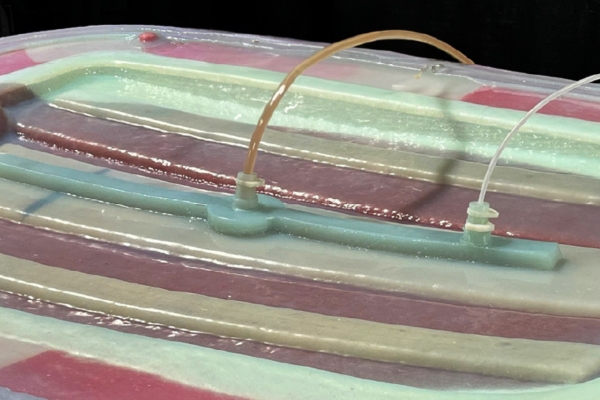

Reusable bag molding incorporates a rigid base A-mold and a thin, flexible membrane bag as the counter mold. The reusable bag is constructed from silicone, latex, or polyurethane and can be used to make numerous parts before needing replacement. Closed cavity bag molding (CCBM) is a variation of reusable bag molding in which a semi-rigid vacuum clamping ring is used to provide the airtight seal around the perimeter of the mold.

Gelcoat is applied to the mold surface if required and reinforcement materials such as fiberglass, carbon fiber, or aramid are layered into the mold. Core materials such as foam or balsa may also be added to increase part stiffness. Once all materials have been layered into the base mold, the silicone bag is placed and secured, and a vacuum is drawn. Using a low-pressure resin pump, catalyzed resin is introduced through the resin ports incorporated into the bag, and the part is allowed to cure. After curing, the vacuum is released, and the silicone bag is removed. The part is then demolded and is ready for post-processing.

Example Reusable Bag Molding Applications

Automotive body panels and bumpers

Boat hulls and decks

Aerospace components such as wing sections, fuselage panels, and fairings

Wind turbine blades

Recreational equipment such as helmets, bicycle frames, and racquets

Industrial pressure vessels and storage tanks

Bridges and walkways

Technical and HSE Support for Reusable Bag Molding

Composites One offers personalized technical support for customers manufacturing with the process of reusable bag molding, as well as the most up-to-date information on regulatory and compliance requirements.