Pultrusion

Process Overview: Pultrusion

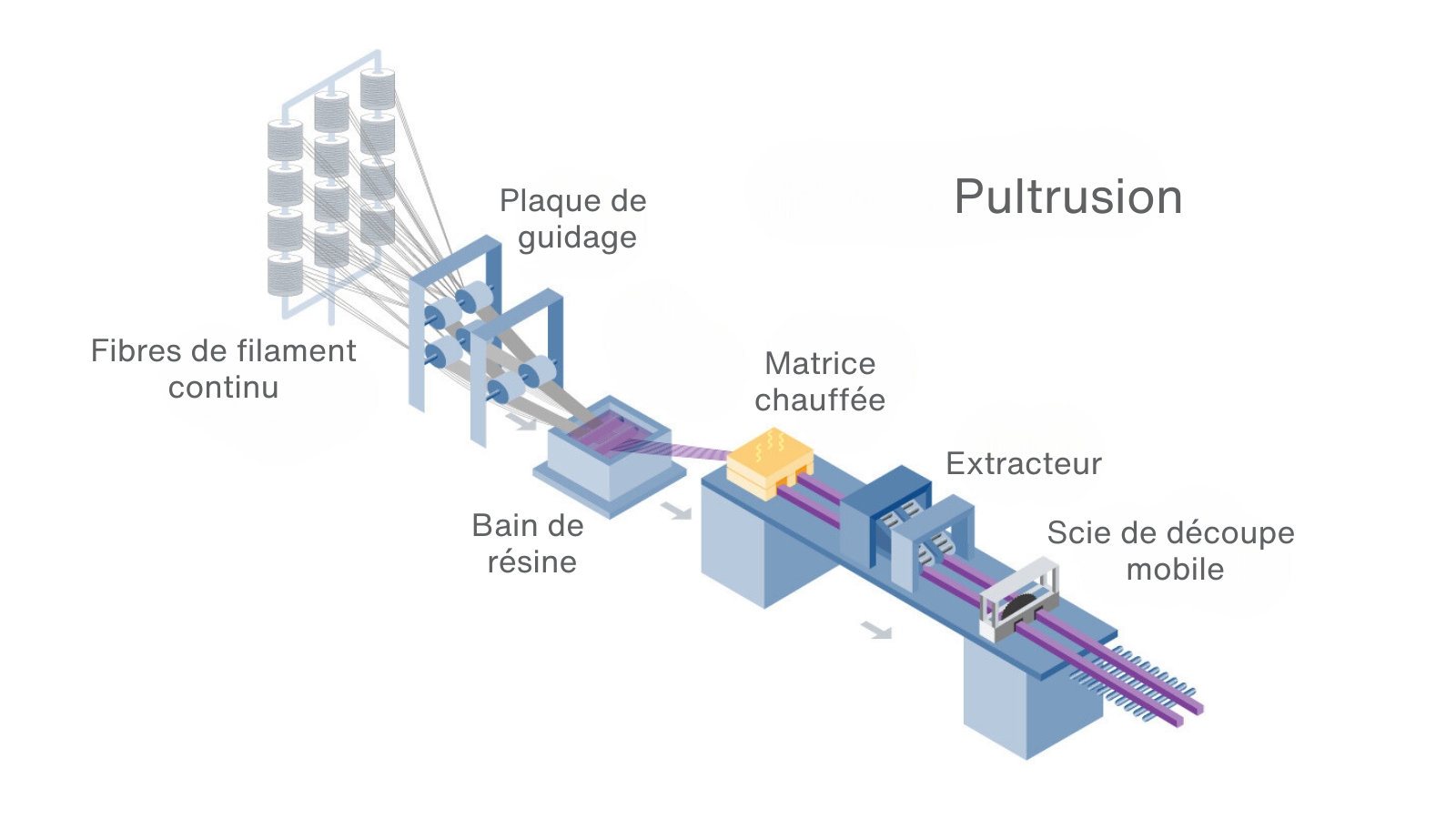

Pultrusion is a highly automated closed mold process of pulling continuous fiber rovings, veils, or fabrics through a catalyzed resin bath and into a heated metal die to form parts with consistent cross sections, high strength, and dimensional stability.

The pultrusion process produces products with extremely high fiber content that are used in a wide variety of industrial, consumer and infrastructure applications. This continuous process incorporates a variety of fibers including glass, carbon, or aramid and other reinforcements including knitted fabrics, continuous filament glass mat, and veils for improved surface finish. Multiple resin systems can also be used depending on the end-use requirements. Fiber is pulled from creels into a catalyzed resin bath and into a heated metal dye that shapes and cures the part. The cured profile is pulled into the machine cutting area where sections are cut and stacked for further processing or finishing.

Example Pultrusion Applications

Example Pultrusion Applications

I‐beams, channels, and girders

Rebar

Frameworks

Gratings and decking

Utility poles and cross arms

Ladders

Fencing

Rods, bars, and tubing

Technical and HSE Support for Pultrusion

Composites One offers personalized technical support for customers manufacturing with the process of pultrusion, as well as the most up-to-date information on regulatory and compliance requirements.