News

Carbon Fiber Composites Take Flight with NASA Rotorcraft Mars Mission

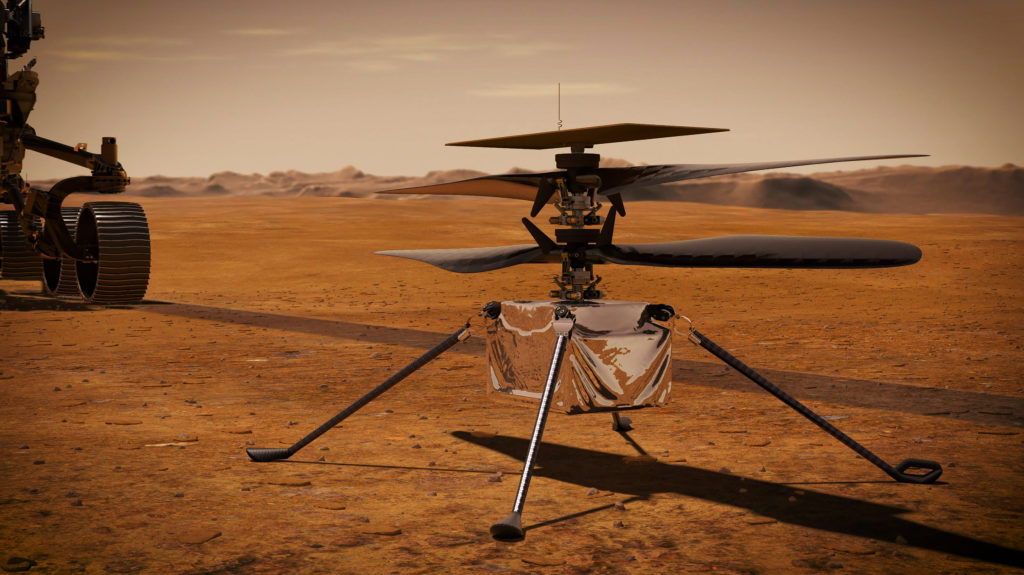

When NASA is employing carbon composites for its space missions, it is safe to say the materials are proven effective and considered reliable and high functioning. NASA’s Ingenuity helicopter, descending from its Perseverance rover, recently landed its four carbon composites legs on the surface of Mars.

Back here on Earth, the uses for composites in rotorcraft are just as innovative—or they come close.

NASA has also focused on incorporating composites into a helicopter gearbox design with the goal to reduce weight and mitigate helicopter vibration and subsequent noise. Initial results have shown that composite material used in this capacity prove capable of handling temperatures and loads within a helicopter gearbox.

A composites aerospace manufacturing project from Hartzell Propeller includes a three-blade advanced structural composite scimitar propeller that has been approved for thousands of single-engine airplanes. The composite-based blade technology achieves less weight along with increased performance speed, durability, and in-air comfort. Another example is Airbus’s new Racer (rapid and cost-efficient rotorcraft) Helicopter, which uses composites to construct its side shells and part of the fuselage.

Thermoplastic composites in space

Even more rotorcraft possibilities emerge for composites with the use of recycled thermoplastic composites. A project by ThermoPlastic composites Application Center (TAC) in the Netherlands manufactured thermoplastic composite access panel doors from recycled waste. The materials achieve a weight savings of 9% compared to the original part. The more cost-effective panel door offers a sustainable manufacturing solution with less material used to reduce overall waste and cost.

The “TPC-Cycle program” recycle project from TAC is set out to prove the viability of a recycling process for various non-structural aerospace products to reap additional benefits of weight and cost savings, and manufacturing sustainability.

Learn more about the benefits of composites in rotorcraft manufacturing.