News

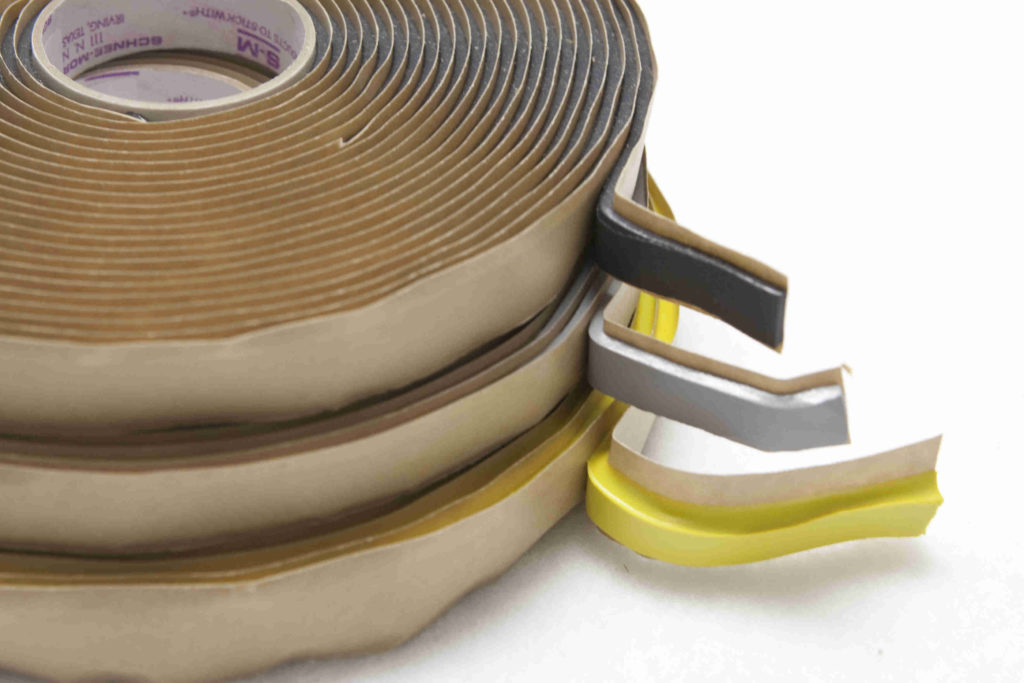

Sealant Tapes from Aerovac

Vacuum bagging and process materials are critical for certain composites production processes like vacuum infusion – a process of choice for many manufacturing applications. Vacuum bagging process materials, like sealant tapes, work to evacuate air and compress the laminate, creating a high fiber-to-resin ratio that results in reduced emissions and improved performance.

Aerovac is a leading source for high-quality vacuum bagging and process materials. In addition to sealant tapes, Aerovac manufactures and supplies vacuum films, peel piles, release films, flow media, tubing, combination materials and connectors for various industry applications.

Sealing in performancex

Sealant tapes from Aerovac are designed to perform in many challenging manufacturing environments. They are available in various widths and qualities and are formulated to suit a range of cure temperatures, from ambient cures to high temperature thermoplastic cures of 400 degrees Fahrenheit. Further, sealant systems are useful in bonding dissimilar substrates, even porous surfaces, with high flexibility and very high temperature resistance. These attributes create demand for sealant tapes and other process materials for various production methods in aerospace, wind energy, marine, and automotive manufacturing.

The experts at Composites One and Aerovac help manufacturers utilize process materials like sealant tapes for a wide range of applications, including vacuum infusion and prepreg processing. In vacuum bagging, for instance, sealant tape can be used to create an airtight seal between the vacuum bag film and the mold surface or the bag itself.

Aerovac provides a full array of the process materials and consumables that customers need to make high-quality composites products and tooling. Our innovative materials, such as sealant tapes, peel ply, release films, release fabrics, bagging films, infusion mesh, and other vacuum consumables, are backed by unparalleled support and service to help customers select the right products for their specific manufacturing method, production requirements, and desired result.

Learn more about vacuum bagging and process materials from Aerovac and Composited One.