News

Custom Kitting Solutions from Aerovac Offer All-Around Savings in Aerospace Production

Cutting and sorting materials takes considerable time in composites manufacturing, especially for processes that involve multiple materials or complex shapes and parts. This also applies to the process materials used to make the parts through vacuum infusion and advanced composites processing with prepreg. The process of preparing process materials for production requires intensive time and labor and inherently results in high material waste and manual errors.

Industries with high-volume demands, like aerospace and marine, are utilizing alternative solutions such as kitting services to help meet production demands with quality and consistency while saving time, cost, and utility space in production processes.

Custom kitting services from Aerovac prepare composite materials that are pre-cut to specific manufacturing requirements and delivered ready for assembly, eliminating the extremely laborious and wasteful task of cutting materials to size and sorting for production on the manufacturing floor.

Measurable savings add up for aerospace manufacturers

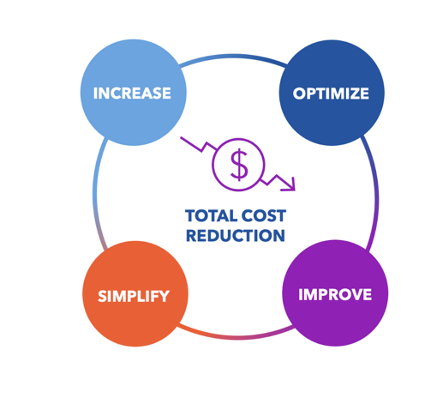

Composite manufacturers who use custom kitting solutions from Aerovac increase their efficiency and reduce material waste. They also benefit from efficiency and productivity gains by reducing employee manpower. Reducing material handling by employees also limits opportunities for human error and defects made to production materials. With consistent manufactured parts, aircraft fabricators can achieve quality parts that meet production requirements with every cycle. Productivity is improved with a streamlined layup and bagging processes, which allows for more mold cycles that produce reliable parts every time, especially important for complex parts.

By purchasing vacuum bagging films and other consumables in kit form, manufacturers can:

- Increase productivity and reduce downtime

- Make smarter, more economical material purchases

- Reduce unnecessary material handling

- Eliminate manually cutting materials to size

- Prevent errors due to last-minute cutting

- Standardize workflow, improving quality

- Free up storage space for other needs

- Reduce waste and save money

According to Composites World, “How well a fabricator manages its materials is key to how well it is able to serve its customers with the ability to consistently meet delivery due dates.”

Composites One aligns customers with the innovative technologies, processes, and suppliers needed to maximize output in composites manufacturing. Custom kitting solutions from Aerovac are an example of how aerospace customers are improving efficiency and achieving success through partnerships with Composites One.