News

Driving Down Costs in the Automotive Composites Market

The aerospace industry has been using carbon fiber for decades in its composites manufacturing upon discovering the lightweight benefits of composites parts. With the shared goal of producing vehicles that are lighter weight to improve fuel efficiency, the automotive industry is increasingly turning to composites raw materials and manufacturing processes to achieve these end gains.

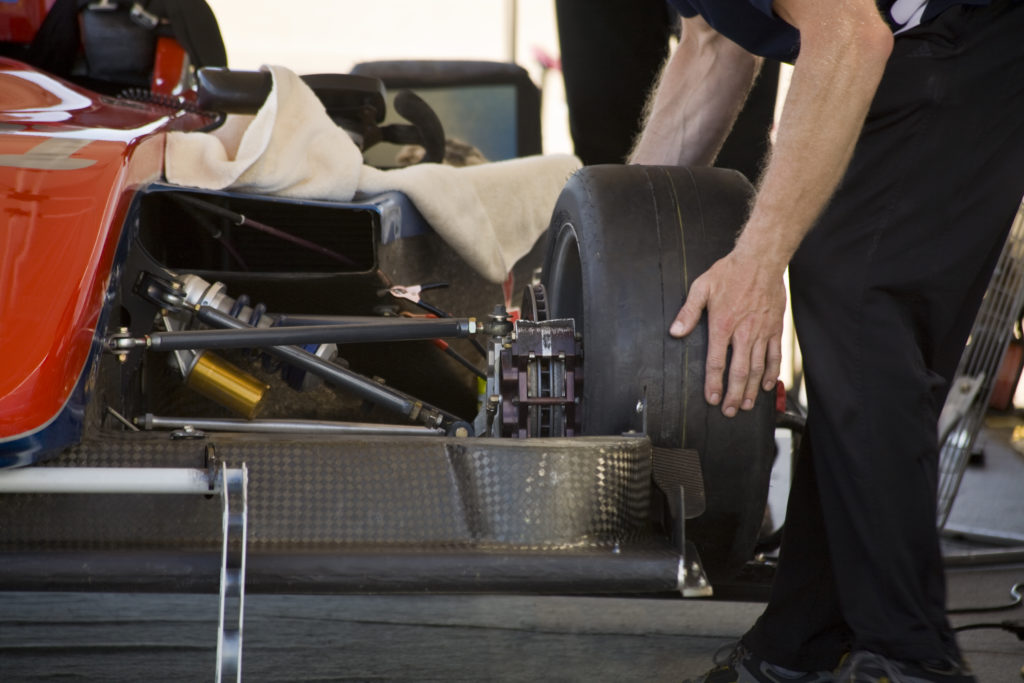

Since the 1970’s, automotive manufacturers have been adopting carbon fiber and epoxy prepregs as part of their various manufacturing processes for motorsport applications. It achieves the goals of lighter weight and more economically sound vehicles, and it also improves safety for drivers through its versatility and strength that exceeds that of traditional steel parts.

The market for automotive composites has been forecasted to surpass $24 billion USD by 2024. This anticipated growth is being driven by increasing ongoing efforts by vehicle manufacturers across the globe to reduce overall vehicle weight.

Process leads to productivity

An evolving goal in automotive manufacturing is to improve the cost-effectiveness of using carbon construction as part of manufacturing processes. This applies to—and presents an opportunity for both gas and electric vehicles. Lighter weight parts boast the same benefits for electric cars as they do for gas vehicles by making the final products lighter, more efficient, and ultimately more affordable by optimizing battery life.

Production processes can play a role in the increasing affordability of using composites parts in automotive manufacturing. Compression molding and resin transfer molding (RTM) are among the innovative processes that can drive lower cost of production when glass and carbon fibers are used in the production of structural components.

Additionally, a company in Israel is exploring use of the pultrusion process to utilize ultra-light carbon fiber, similar to the way Kevlar and carbon fiber have been used in the making of armored vehicles for many years. The goal of the project is to produce a carbon-composite car structure that is 45 percent lighter than an equivalent steel vehicle and 20 percent lighter than an aluminum car.

Weight reduction and subsequent affordability will give way to even greater opportunity for the growth of the automotive composites market. As opportunities for composites production in automotive evolve, Composites One is available to provide the automotive industry with the composites materials to help automotive-related manufacturers enhance performance and produce stronger, lightweight components.

Learn more about automotive composites products and processes from Composites One.