News

Quality Tooling Board is One Key to Quality Composites Production

Quality composites production begins with quality tooling. When determining which type of tooling is best for your composites manufacturing method, it’s important to first consider your desired result. Factors such as the required cure temperature, ideal dimensional stability, planned budget, and required durability depending on the number of cycles, will help you determine which tooling material is ideal for your needs.

Common materials used in composites tooling production range from traditional resin solutions, tooling board, to prepreg for tooling. The right tooling material can help you achieve a quality mold surface to produce quality composite parts.

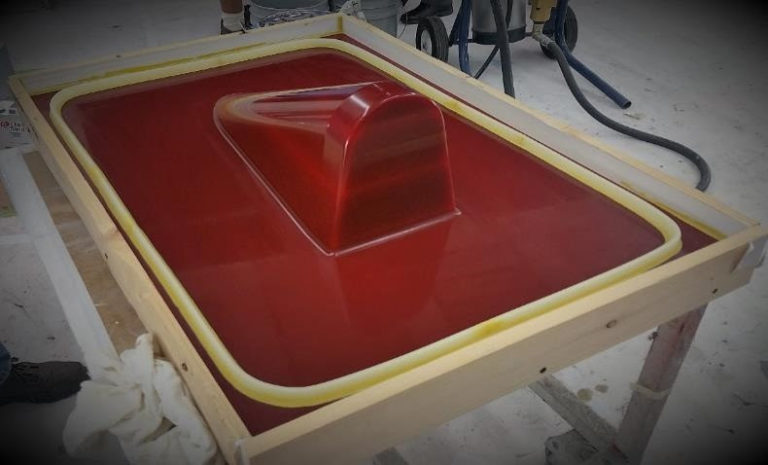

Tooling board offers manufacturers options for mold production

Tooling boards offer a range of variety in mold production, working well with the most unique complexities to simple, large format designs.

Tooling board material is primarily made with polyurethane or epoxy, with epoxy tooling boards being suitable for higher temperatures than polyurethane. Tooling board offers the benefits of being lightweight, producing excellent mold surfaces, and offering varying densities as well as the ability to withstand high-temperature cures.

A medium-density may help achieve short-run molds while higher densities can create high levels of detail and withstand higher processing temperatures that are valuable for making composite parts. Composites One can help customers determine factors like the right density tooling board needed for the composites manufacturing project.

Composites and tooling

Composite materials themselves continue to be a material of choice for tooling because of the coefficient of thermal expansion (CTE) match between the tools and parts, which enables the manufacturing of more precise composite parts. Tooling boards have emerged that leverage the CTE match of composites materials to achieve exceptional dimensional stability, plus the ability to withstand higher temperatures.

Whatever your composites tooling needs, Composites One offers the expertise in advanced tooling design and composites manufacturing to help you with selection. Learn more about the use of high-quality composites tooling in the aerospace segment.