News

Vacuum Infusion Process (VIP) Results in High Strength Composites

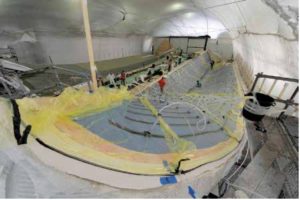

The vacuum infusion process (VIP) is one of the best ways to build strong, consistent composite laminates while offering the environmental and worker advantages of a closed mold process with reduced emissions. The vacuum infusion process uses vacuum to drive resin into a laminate, creating parts with very high fiber content and high strength and high stiffness to weight ratios.

VIP also offers lower tooling costs than other closed mold processes, making it possible to produce large, complex parts at a reduced cost. For this reason and others, it is often applied in industries, such as wind energy, aerospace, marine, and other industrial applications for manufacturing primary product structures. Vacuum infusion offers consistency even when creating large structural parts resulting in less waste and reduced costs.

Composites One helps customers ensure VIP success.

There are many factors to consider when using vacuum infusion processing to ensure successful outcomes. The technical experts at Composites One support customers in ensuring all details and materials are aligned, including viscosity of the resin, permeability of the laminate, and vacuum level, as well as other related factors.

Choosing reinforcement is especially important when using infusion processes. Fiberglass is the most common reinforcement to be used in the vacuum infusion process. Infusion specific reinforcements offer high permeability, allowing resin to easily flow throughout the mold. Carbon fiber and Kevlar® reinforcements can also be used for projects that require higher strength, stiffness, or toughness.

Composites One exclusively distributes its own line of vacuum infusion products – Aerovac Process Materials. Aerovac develops, manufactures, supplies, and supports innovative vacuum bagging and process materials for customers who demand the best for their prepreg processing, vacuum infusion, resin infusion, glass lamination, and other closed mold composite manufacturing processes.

Composites One offers a variety of resources to help manufacturers transition to a vacuum infusion processing. Along with the Closed Mold Alliance, Composites One can help manufacturers source the right products and equipment to make VIP successful in composites manufacturing operations.

Learn more about vacuum infusion process (VIP) from Composites One.